Pneumatic rubber fenders for marine, is a ship & marine eqipment, are called yokohama floating pneumatic rubber fenders. Floating pneumatic marine rubber fenders are inflated with air, working between ships berth to mooring structure or ship to ships (STS Transfer). Thats the two main use of pneumatic rubber fenders. Marine pneumatic rubber fender is made of rubber, owning advantages of aging-resistant, aging oil, floating on water, a better fender protection system for hull of marines and ships.

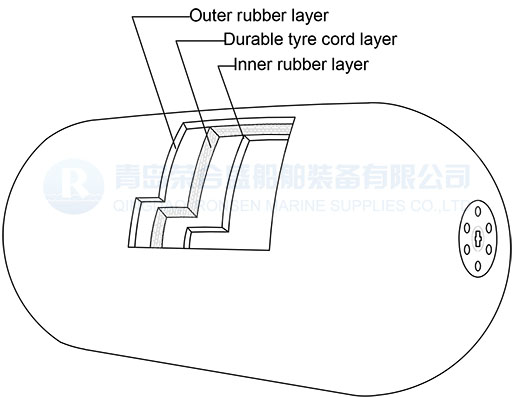

Our pneumatic marine fenders are manufactured as per ISO 17357-1 “high pressure floating pneumatic rubber fenders“. Marine rubber pneumatic fender is manufactured with inner rubber layers, reinforced by synthetic-tire-cord-rubber dipped layers to protect rubber pneumatic fenders’ body and then outer heavy duty rubber layers to pack the first several layers of pneumatic marine rubber fenders, finally, sealed with high tensile strength flanges and inflated with pressed air of 50 g/cm2 or 80 g/cm2. Yokohama marine pneumatic rubber fender is playing as a bumper to absorb energy generated during their touch for Ship to ship transfers, sometimes, pneumatic marine fender are placed side of ports to absorb energy between ships and berthing structures while they came alongside on the sea water.

Construction Features of Pneumatic Rubber Fenders

CONSTRUCTION:

CONSTRUCTION:

As per international standard production technology of floating type “PNEUMATIC RUBBER FENDERS” explained above, our pneumatic marine rubber fenders are designed of

– Inner rubber layers

– rubber dipped synthetic tire cord layers for reinforcement purpose

– Outer rubber layers

FEATURES:

- Easily Installation.

Pneumatic rubber fenders will be inflated only for clients after receiving.

Pneumatic rubber fenders will be inflated only for clients after receiving.

Or opptional equipped with guy-ropes or hot dipped galvanized chains at two ends of yokohama pneumatic marine rubber fenders. - Good Performance.

While pneumatic rubber fenders are under compression of 15 degrees, they would perform still well, resisting shearing force and maintaining higher energy absorption, this is the big advantage of pneumatic marine fenders comparing to marine rubber fenders.

Fender Classification

Fender Classification

FENDER TYPE

High pressure pneumatic fender types are defined as follows: Type I – Net type, Type II – Sling type, Type I Single – Net type and one end with no flange opening and no metal parts

INTERNAL PRESSURE

Pneumatic 50 (initial internal pressure 50 kPa), Pneumatic 80 (initial internal pressure 80 kPa)

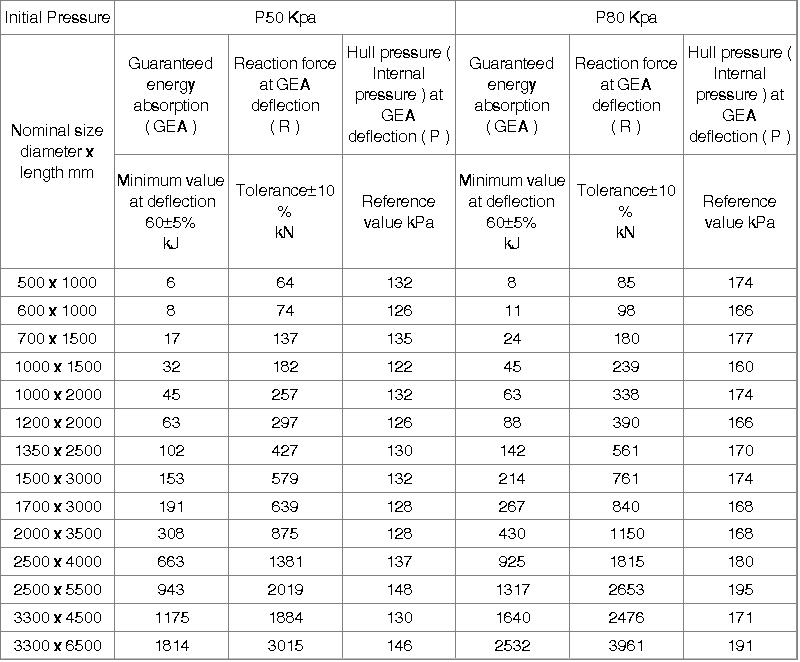

Specification Table

Pneumatic rubber fenders sized from 0.5 M ~4.5 M in diameter and 1.0 M ~11.o M in length, calssified by initial pressure of marine pneumatic rubber fenders 50 Kpa and 80 Kpa. They are generally specified in terms of Guaranteed Energy Absorption (GEA), Reaction Force at GEA deflection.

For any customrized sizes of pneumatic rubber fenders, warmly welcome you to ask.

For any customrized sizes of pneumatic rubber fenders, warmly welcome you to ask.

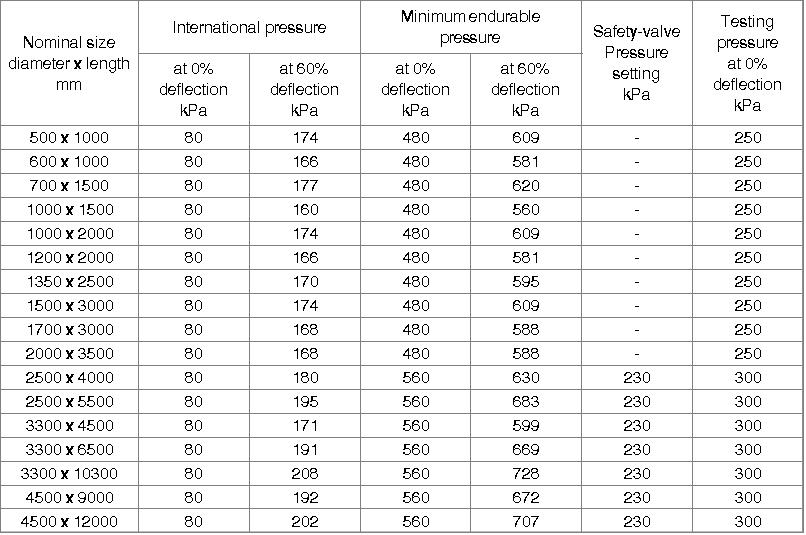

Pressure Performance

While referring to pressure of pneumatic rubber fenders according to ISO 17357-1, they are always mean testing pressure, internal pressure, endurable pressure at related deflection.

Test for Commercial Pneumatic Rubber Marine Fenders

Generally, when talking about tests of pneumatic rubber fenders, we are referring to commerical pneumatic type  marine fenders. Before delivery of pneumatic fender, usually, we do following type of tests:

marine fenders. Before delivery of pneumatic fender, usually, we do following type of tests:

– DIMENSION

Ordered pneumatic rubber fenders would be inspected at their initial pressure for their length and diameter.

Length: +10%, -5% Diameter: +10%, -5%

– AIRTIGHTNESS

For any pneumatic ship fender, our company will check the air-leakage first, it is the necessariy inspection for commerical rubber fenders. Air leakage test shall be conducted at initial pressure of marine rubber fender for more than 30 min to confirm no air leakage.

– HYDROSTATIC PRESSURE TEST

This test is for commerical fenders filled with water proceeded under 0% deflection, maintaining 10 mins at required hydrostatic pressure, keep no leakage of water and defects of fender body during the test.