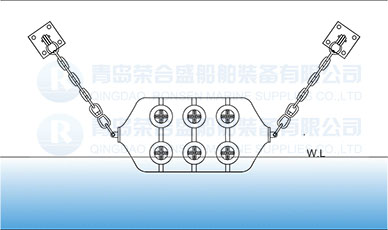

Foam filled marine fenders, cushion netted is high performanced solid foam fenders, with chains, tire nets coated outside of foam filled fender body. They are used as marine fenders protection systems for offshore industry. Marine cushion neted foam filled fenders can floa as tidal changes, more suitable for harsh working environments than guard netless type. Foam filled marine fenders are widely applied to fields of marines, shipbuildings, petrochemcial and energy, oil and gas, platforms, ships, harbors and construction etc.

Foam filled marine fenders, cushion netted is high performanced solid foam fenders, with chains, tire nets coated outside of foam filled fender body. They are used as marine fenders protection systems for offshore industry. Marine cushion neted foam filled fenders can floa as tidal changes, more suitable for harsh working environments than guard netless type. Foam filled marine fenders are widely applied to fields of marines, shipbuildings, petrochemcial and energy, oil and gas, platforms, ships, harbors and construction etc.

FEATURES

Cushion netted foam filled fenders are constructed with “closed-cell resilient foam core, nylon filament reinforced layers, tough polyurethane skin coated’. The construction of this foam filled marine fenders have following features:

- Pr

otection for rough surface

otection for rough surface - Adjust to water levels

- Lower maintenance, easier installation and large standoff distance

CONSTRUCTION

- Our foam filled marine fenders inner core are filled with highest quality resilient closed-cell foam.

This specific foam either EVA or PE can provide higher energy absorption wih relatively lower reaction force for foam filled fenders. - Foam filled fenders’ skin is constructed of pure polyurethane(PU) elastomer reinforced with nylon fibre filament.

- Comprising through central steel tube and external load distribution flanges at each end.

- Cushion netted foam filled marine fenders are installed with chain and tire net. The chain and tire net design uses heavy duty hot-dipped galvanized chain, fitted with heavy tires at the net intersections. This chain and tire nets carry the tensile load, minimizes stress in the foam fender skin.

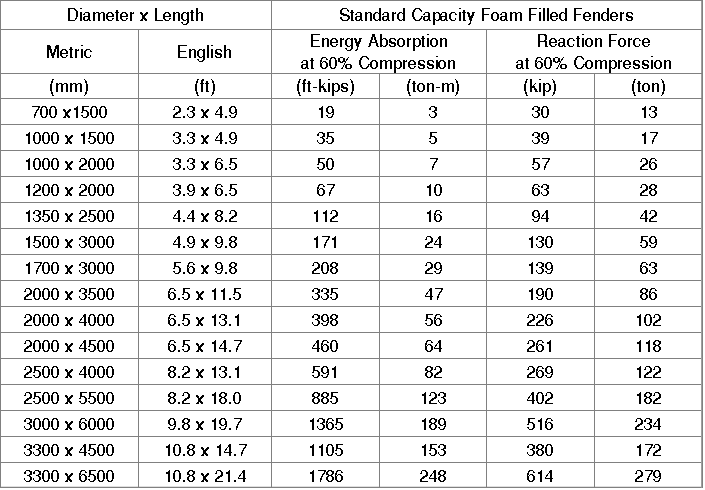

PERFORMANCE TABLE

We supply our cushion neted foam filled marine fenders in standard capacity now.

INSTALLATION

Floating foam filled marine fenders are easy be installed due its buoyant structure allows floating installation work. the unique craftship of end fittings and heavy duty internal chains also are ideal options for hanging installation. Whichever installation, it include a 2 points and 4 points mounting arrangement. The typical mounting hardwares include: dock plate padeyes, botls shackles, swivels and stud link chain. Please refer above photo.

TESTS

Dimensions: We proceed the dimensional test for each foam fender delivery on diameter and length, appearance to see if any defects.

Performance: Fenders are placed under compression equipment to test demanded energy absorption and reaction force to fullfill clients requirements.