Ship launching airbags produced according iso international standard ISO 14409 Ship launching air bags, made of rubber to launch marine. Ship launching marine airbag (air balloon) works at an safety working pressure designed in cylindrical roller bags shape. Launch ships using marine rubber airbags is another launching method in marine industry. Our marine rubber ship launching airbags have a higher safety coefficient than ISO required 3 times working pressure. This could be done by kind of required bursting test.

With years of marine ship launching airbags operations, we can use rubber ship launching airbags launch 1,000 DWT Ships ( currently 55,000 DWT Barges ). Launching with ship airbags technology is becoming a secure and mature marine technology. Besides, Ship launching airbags are also widely applied for vessels’ landing upsliping, tug boars or fishing boats pulling up as well as salvage rescue works and heavy lifting.

With years of marine ship launching airbags operations, we can use rubber ship launching airbags launch 1,000 DWT Ships ( currently 55,000 DWT Barges ). Launching with ship airbags technology is becoming a secure and mature marine technology. Besides, Ship launching airbags are also widely applied for vessels’ landing upsliping, tug boars or fishing boats pulling up as well as salvage rescue works and heavy lifting.

Construction & Specification of Airbags

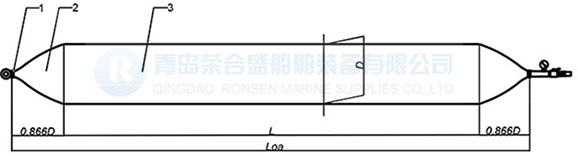

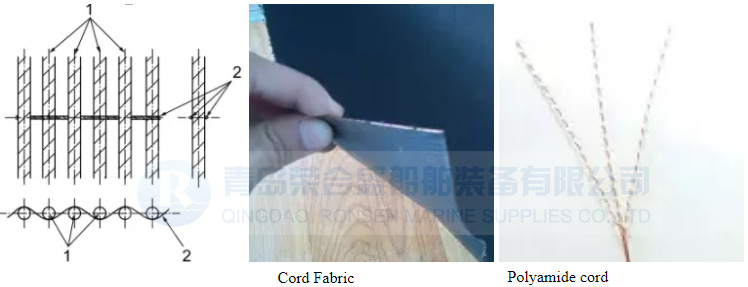

Ship launching airbags is constructed of outer rubber layer, synthetic-cord-reinforced rubber layers and inner layers. Ship launching marine airbags is a long pneumatic rollers structure with hemispherical heads at two ends with strong iron fittings. All these parts are vulcanized together, and then inflated air to make it roll.

Each our ship launching airbag is consisted of three factors: Diameter, Effective Length and Number of layers. You can choose any required diameter and effective length to suit your launching and landing hauling out projects.

SPECIFICATION:

Diameter (D): It’s from 0.8 m to 3.0 m which mainly include 0.8 m, 1.0 m,

1.2 m, 1.5 m, 1.8 m, 2.0 m, 2.5 m, 3.0 m

Effective length (EL): It’s from 6.0m to 24.0 m

Total length (TL): It’s from 7.38 m to 29.20 m

Number of Layers: Ranged from 4 layers to 25 layers, normally, we define the number of ship launch air bag layers means number of synthetic-tire-cord layers, 6 layers is generally standard layers which is suitable for most of engineering works. Meanwhile, any other customrized sizes or types are available also.

MATERIALS:

Inner rubber layersSynthetic tire cord rubber dipped layers, Outer rubber layers.

HOW TO SELECT MARINE AIRBAGS:

General information for launch

calaculation.

- Type of vessel.

- LOA of the vessel.

- Width of vessel.

- Vessels actual launched weight.

- What’s the vessel’s DWT

- Condition of slipway

- Blocks of height under the vessel.

- Distance from propeller to the end

of launch ramp.

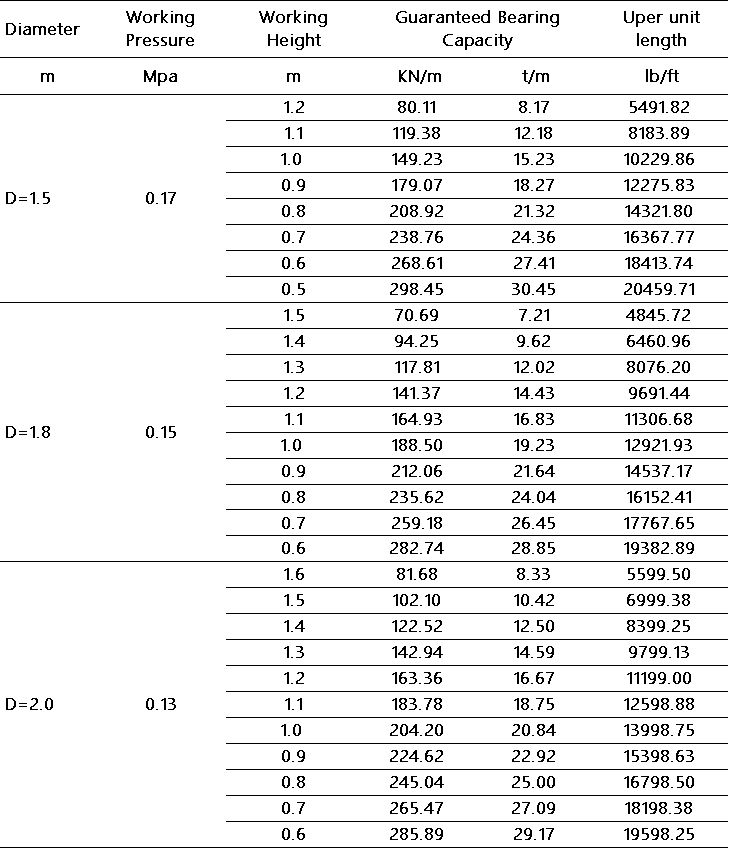

Performance Sheet

Since layers of ship launching airbags ranged from 4 ~10 layers and diameter from 0.8 M ~2.5 m, performances of marine rubber ship launching airbags is diverse also at different working heights. We here list performances of rubber ship airbags standard 6 layers in below table. For more details of launch ship airbags 7 layers, 8 layers, or 10 layers, please let us know.

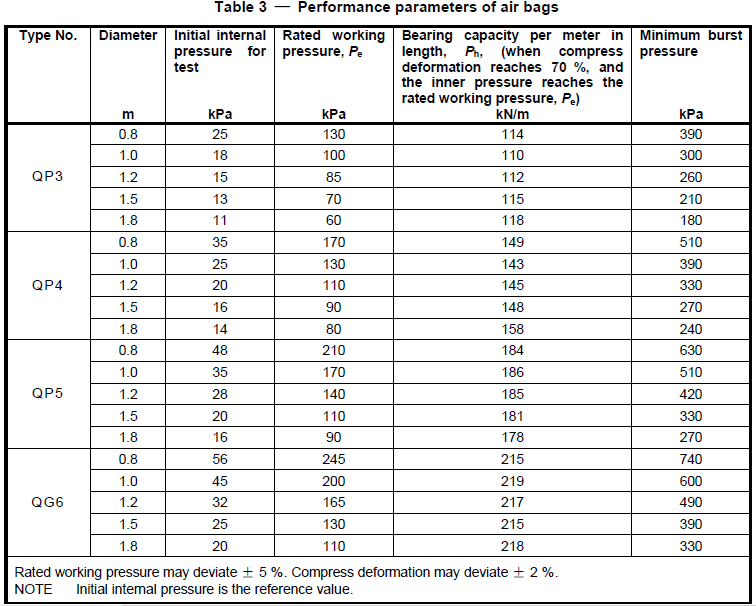

Tests

Our ship launching airbags are manufactured and tested under standards requirements of iso 17682 and iso 14409. the necessaried inspected items before delivery for an airbag are: appearance, dimension and tightness.

the appearance of an air bag shall be smooth, glossy and without blemish such as crack, blister, delimination, pits or impurities.

length and diameter of an air bag shall be measured with rated working pressure, within 3%.

while without carrying any load, fill air bag till internal required pressure, record the pressure and compare it after 1 hour. loss is no less than 5% qualified.