Ronsen Marine is certified in accordance with Quality Management System ISO 9001, UKAS. The commitment to quality is our top priority, which embedded in every disciple of Ronsen Marine. At the core of company’s principle is a belief that continuous improvement and investment is people and process provide customers with lasting quality and value. Customer satisfication is essential to every Ronsen Marine employee.

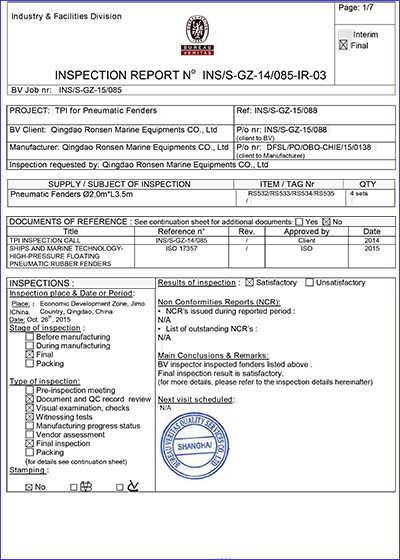

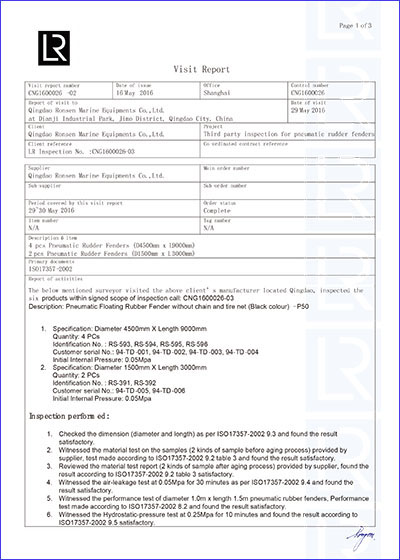

Ronsen Marine fendering system guarantees high standards and performances of all fendering products comply with the quality guidelines that cover quality assurance, design, development, production, installation and after-sales. Customer requirements are strictly followed all production phases. Client and third party attendance during testing is also welcome.

Ronsen Marine’s manufacturing facility is equipped with complete testing facilities. Each facet of day-to-day operations integrates human, technical (processing techniques) and material resources for optimum production and customer satisfication. Ronsen guarantees high standards and performances of all products. Customer requirements are strictly followed all production phases. Ronsen Marine research center assures a procurement control on the raw and basic material.

Standard:

1.PIANC Marcom Report of WG33 – Guidelines for the Design of Fender Systems (2002)

2.ASTM F 2192-05 Standard Method for Determining and Reporting the Berthing Energy and Reaction of Marine Fenders

3. ISO 17357-1 High pressure Floating Pneumatic Rubber Fenders

4. China Standard for Marine Rubber Fenders (HG/T 2866-2003)