According to ISO 17357-1, each Yokohama type floating fender involving different methods of basic construction and design, shall require a prototype test.

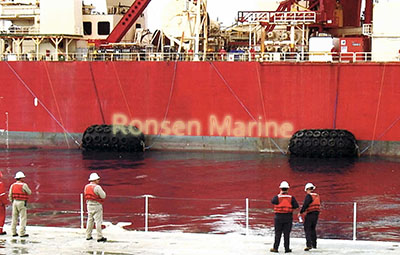

Ronsen Marine follow close to the line of the international pneumatic rubber fenders standard to supply excellent floating pneumatic rubber fenders to marine clients and ship owners.

Performance of Compression Test

Generally, before the delivery and shipment of pneumatic rubber fenders, a performance test would be proceed for each pneumatic fender to further inspect their qualities. Applying a compressive force to Yokohama type pneumatic rubber fenders till pneumatic rubber fenders reach their guaranteed energy absorption(GEA) value. Record their reaction force and internal pressure during its deflection. Then the performance of ribbed fenders would be calculated as follows.

= percentage deflection;

= percentage deflection;  = compression length, in millimeters;

= compression length, in millimeters;  = original diameter, in millimeters;

= original diameter, in millimeters;  = reaction at a given deflection;

= reaction at a given deflection;  = incremental deflection;

= incremental deflection;

As per ISO 17357:2002/ISO 17357-1:2014, pressure test shall be repreated twice for floating fenders, then energy absorption and reaction force can be obtained from two test results.

Pneumatic rubber fenders is qualified to meet required GEA performance if it achieve 100% of GEA energy absorption at 60% deflection.

Performance of Ronsen Yokohama type floating pneumatic rubber fenders are shown below which combines with ISO 17357-1 and PIANC 2002.