Floating pneumatic fenders for ships barge, manufactured with ISO 17357 floating pneumatic rubber fenders production technology. Yokohama floating pneumatic fenders are used for ship and marine industry while mooring of a ship to another ship or berthing structure. Some users referred them to floating fenders or Yokohama floating fenders directly. Yokohama floating pneumatic rubber fenders are anti-resistant to tidal changes, can float on water freely. We are available to provide floating yokohama fenders in black and navy grey colors, types in ribbed, water filled hydro for submarine and ropes/fibre nets/rubber nets also.

There are totally two main types of floating pneumatic rubber fenders among the marine fendering systems, CHN , with chains and tire nets type, netless sling type, without chains and tire nets. Pneumatic floating fenders can be classified by their initial pressure: 50 g/cm2 and 80 g/cm2, each type of yokohama floating fenders perform different under some deflection.

There are totally two main types of floating pneumatic rubber fenders among the marine fendering systems, CHN , with chains and tire nets type, netless sling type, without chains and tire nets. Pneumatic floating fenders can be classified by their initial pressure: 50 g/cm2 and 80 g/cm2, each type of yokohama floating fenders perform different under some deflection.

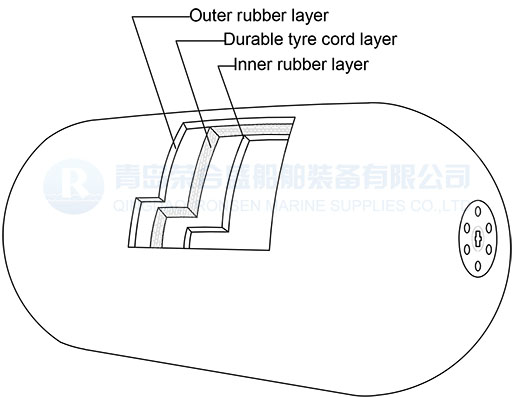

Floating pneumatic fenders construction

Our floating yokohama fenders is designed with inner rubber layers, customrized reinforced synthetic-tire-cord rubber dipped layers and outer heavy duty layers, enlaced and vulcanized firmly. This production  technology is certified by Internationla standard ISO 17357, have some similiarty of marine airbags.

technology is certified by Internationla standard ISO 17357, have some similiarty of marine airbags.

– INNER RUBBER LAYER WITH SEALED AIR

made into pure high elasticity rubber for floating ship fender.

– RUBBER DIPPED REINFORCEMENT LAYER

breaking strength of synthetic tire cord is over 31 KGS, requirements of rubber materials coincide to International standard.

– OUTER JACKET RUBBER LAYER HEAVY DUTY TYPE

Floating pneumatic rubber fenders application

Yokohama floating pneumatic rubber fenders are softer and durable in strength, with less weight, can be applied to oil tankers, container ships, yachts, offshore platforms, large docks, navy wharfs and piers ports etc.

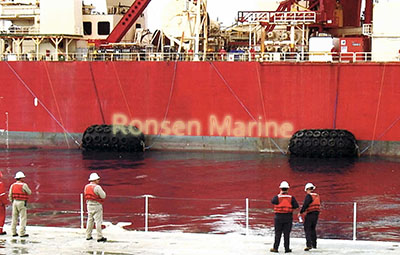

Ship to ship transfer (STS Transfer)

When bigger barges ships come alongside of another barge ship, some primary yokohama floating fender are

employed with several secondary floating pneumatic rubber fenders connected to absorb energy generated and complete transfer works.

Ship to dock (STB/STD Berthing)

Floating pneumatic fenders are placed between ship and berth when a ship is docking for buffering and purpose of energy absorption. Floating pneumatic marine fenders are more ideal selection for ships docking comparing to marine rubber fenders sometime.

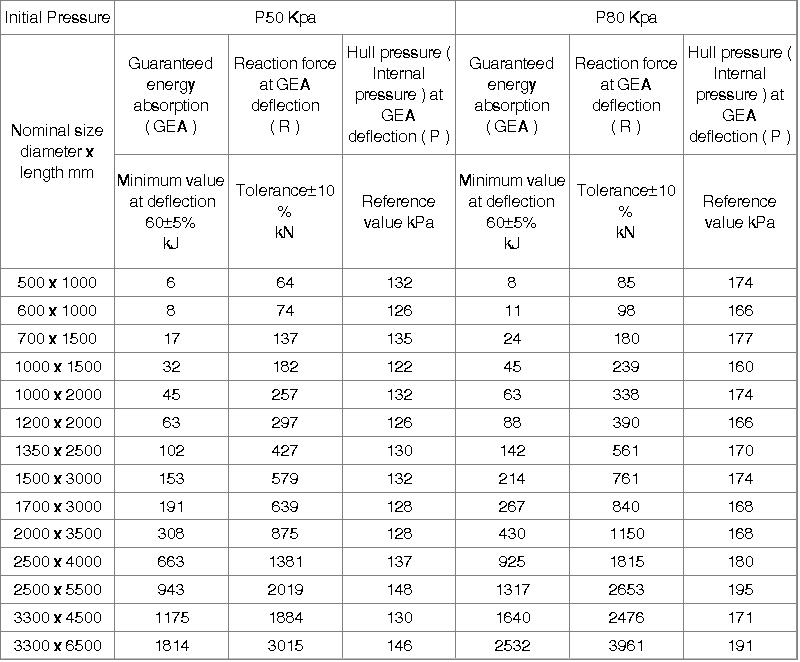

Pneumatic floating fenders dimension

Pneumatic floating fender are specified according to Standard guaranteed energy absorption, reaction force and hull pressure at GEA deflection with initial pressure of 50 kPa and 80 kPa. Our company can test the EA and RF at standard deflection of these yokohama fender.

Material requirements

Basic construction of floating pneumatic fender is consisted of outer rubber, inner rubber and reinforced synthetic-tire-cords. These are main raw material of an floating fender.

Basic construction of floating pneumatic fender is consisted of outer rubber, inner rubber and reinforced synthetic-tire-cords. These are main raw material of an floating fender.

– For outer rubber, it is to protect cord layers and inner rubber from abrasion and other external forces, requiring sufficient tensile and tear strength to withstand weather conditions and severe usages.

– For inner rubber, used to seal air inside.

– For reinforced synthetic cord layers, it should be strong enough to hold internal pressure.

Details of material properties are listed follows.

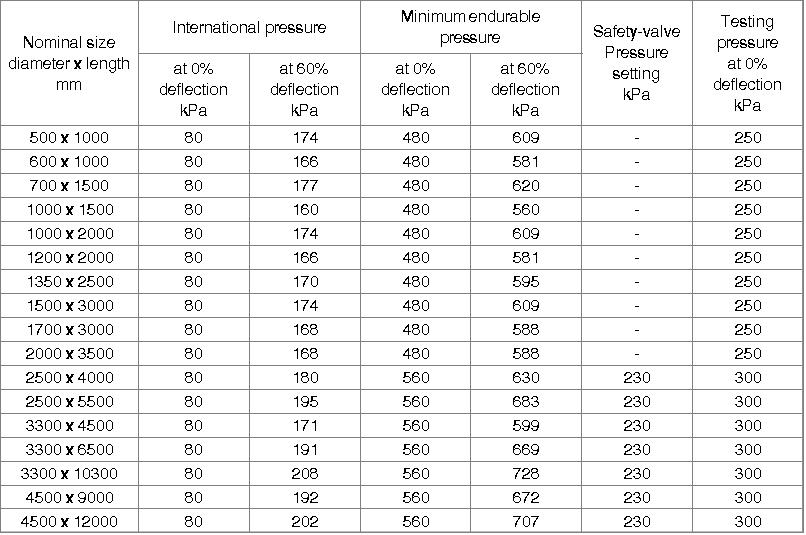

Floating pneumatic fenders pressure requirements

Below table sheet demonstrate pressure changes of yokohama type floating pneumatic fender while tested at related pressure without any deflection and 60% deflection. The pressure include pressure for safety valves, endurable pressures and inner pressures of floating pneumatic fenders.

Welcome to refer other related floating pneumatic fenders for ships barge: