Marine Rubber Pneumatic Fenders

Floating marine rubber pneumatic fenders of our company are produced and tested in accordance with ISO 17357 Ship and Marine Technology " High-pressure yokohama type floating pneumatic rubber fenders ". Todos los guardabarros neumáticos de caucho de Ronsen son fabricados y probados por terceros que cumplen con la norma ISO 17357 "Guardabarros neumáticos de caucho flotante de alta presión" de ISO 17357.

Floating pneumatic marine rubber fenders is manufactured with rubber dipped layers,

sealed air 50 Kpa or 80 Kpa to make it float on water. Pneumatic marine fenders work as a energy absorber between two ships or barges during their touch for STS transfers. And, floating marine rubber pneumatic fenders are placed also side of ports to absorb energy between ships and berthing structures while they came alongside on the sea water, this is called ship to dock (STD) application.

Marine rubber pneumatic fenders features

–Easily to be installed-Our rubber pneumatic fenders have lighter weight comparing with foam filled marine fenders, they can be easily handled and equipped with guy-ropes or hot dipped galvanized chains.

-Good Performance-While marine rubber floating pneumatic fenders are under compression of 15 degrees, they would perform still well, resisting shearing force and maintaining higher energy absorption. Thus, marine pneumatic fenders, rubber type will provide low and comparatively hull pressure accordingly than other solid rubber marine fenders.

-Good Performance-While marine rubber floating pneumatic fenders are under compression of 15 degrees, they would perform still well, resisting shearing force and maintaining higher energy absorption. Thus, marine pneumatic fenders, rubber type will provide low and comparatively hull pressure accordingly than other solid rubber marine fenders.

-Material advantage-Floating pneumatic fenders, rubber type is consisted of heavy duty synthetic-tire-cord raw rubber dipped layers and tough abrasion outer rubber layer which ensure rubber pneumatic fenders have good performance especially when they are under tough conditions and cyclic loads.

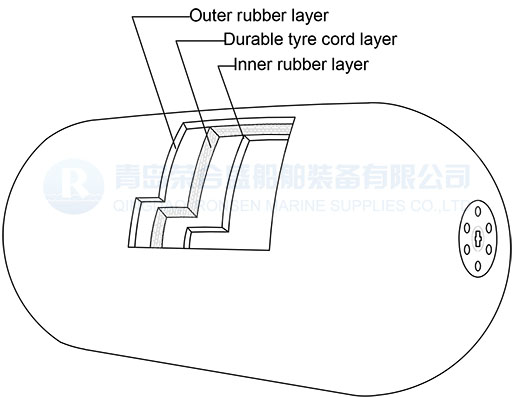

Construction of rubber marine pneumatic fenders

Our marine pneumatic fenders, rubber type are generally consisted of an outer rubber layer, reinforced synthetic-tire-cord-rubber dipped layers and inner rubber layer which were wrapped together firmly.

- Out rubber layer have hard tensile and tear strength to tolerant tough sea weather conditions and sever working areas. It is used to protect inner soft rubber layer from abrasion and other external forces.

- Reinforced synthetic-tire-cord-rubber dipped layers is the skeleton of an Yokohama type pneumatic rubber fenders. They are enlaced one layer by one layer either with mold or manually to strengthen inner rubber layer.

- Inner rubber layer pressurize air inside.

Rubber marine pneumatic fenders specification

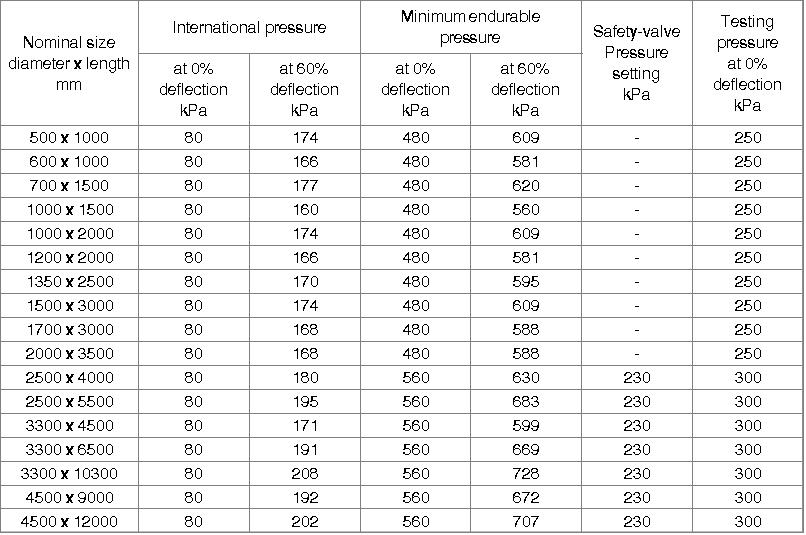

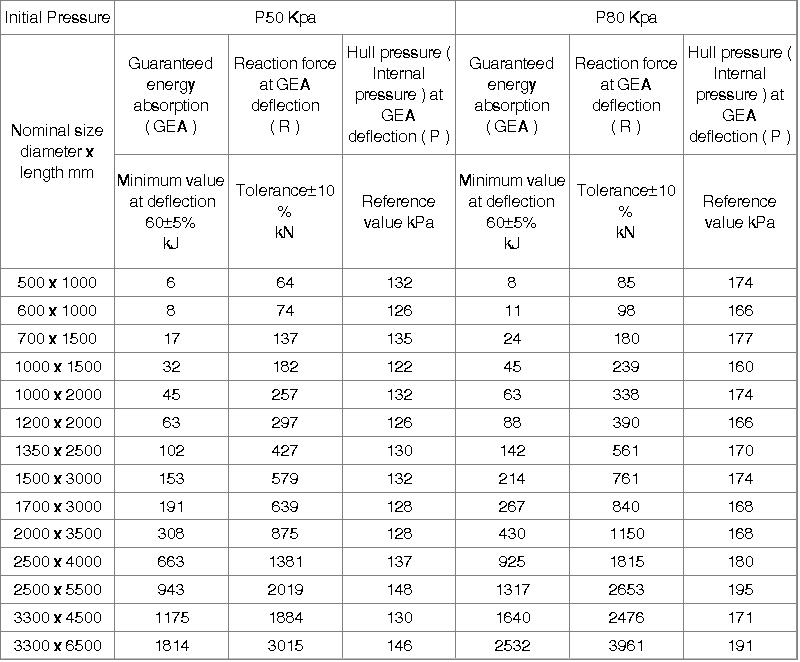

Ronsen rubber pneumatic marine fenders are specified in terms of Guaranteed Energy Absorption (GEA), Reaction Force at GEA deflection, and Hull Pressure at GEA deflection.

Pneumatic marine fenders, rubber type pressure requirements

As per ISO 17357-1, we currently produce two types of rubber Yokohama floating pneumatic fenders based on initial pressure, 50 Kpa and 80 Kpa. Other endurable pressure, safety-valve setting pressure and hydraulic test pressure also meet requirements of ISO 17357.

Initial pressure at 80 Kpa