Rubber Foam Filled Fenders

Rubber Foam Filled Fenders are one of toughest floating fenders on marine market. Ronsen Rubber Foam Filled Fenders are designed for hard work. It's more heavy duty than some marine fenders in China. Las defensas rellenas de espuma de goma son las defensas flotantes más resistentes del mercado marino. Las defensas rellenas de espuma de goma Ronsen están diseñadas para el trabajo duro. Es más resistente que cualquier tipo de defensas marinas rellenas de espuma en China. Ronsen Marine es actualmente el único fabricante más grande y profesional en el mercado marino chino.

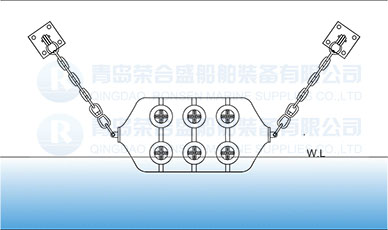

Rubber foam filled fenders of Ronsen Marine are constructed with closed cell EVA/PE foam core inner side, synthetic-tire-cord-rubber reinforced layers in middle, covered with pure rubber skin. And then, rubber  foam fenders body are protected by the chains and tire nets if it is cushion type. This unique design ensure our rubber foam filled fenders top sales in marine fendering market.

foam fenders body are protected by the chains and tire nets if it is cushion type. This unique design ensure our rubber foam filled fenders top sales in marine fendering market.

Rubber foam filled fenders feature

Ronsen rubber foam filled fenders are burst resistant and unsinkable design. It’s perfect for STS ship-to-ship transfer, offshore structures, or anywhere requiring absolute fender reliability. Special construction offers a number of important features and advantages for rubber foam fenders listed follows.

High energy absorption and low reaction force

Tough, nylon&rubber filament reinforced as well as rubber skin

Protection for rough surface and harvest working conditions

Adjust to water level, low maintenance

Unsinkable design even if skin is punctured

Rubber foam filled fenders construction

Rubber foam fenders are fabricated with:

closed-cell resilient foam -> heavy-duty rubber skin -> synthetic-tire-cord-rubber-dipped layers reinforced -> chains, tire nets protected

Rubber foam filled fenders are filled with high density resilient closed-cell foam. This specific foam have higher energy absorption with relatively low reaction force.

Even when the rubber skin is broken or punctured, it would be still unsinkable without absorbing water. With our unique laminating process, each foam core is integrity. The foam core can not be ruptured when compressed.

Rubber foam fenders’ skin is constructed of tough rubber layers which is reinforced with heavy duty fibre filament.

Comprising through central steel tube and external load distribution flanges at each end. All end fittings are hot-dip-galvanized.

Rubber foam filled fenders incorporate chain and tire nets. The chain and tire nets design uses heavy duty hot-dipped-galvanized chains, fitted with heavy ties at the net intersections. This chain and tire net carry the tensile load, minimizes stress in the fender skin.

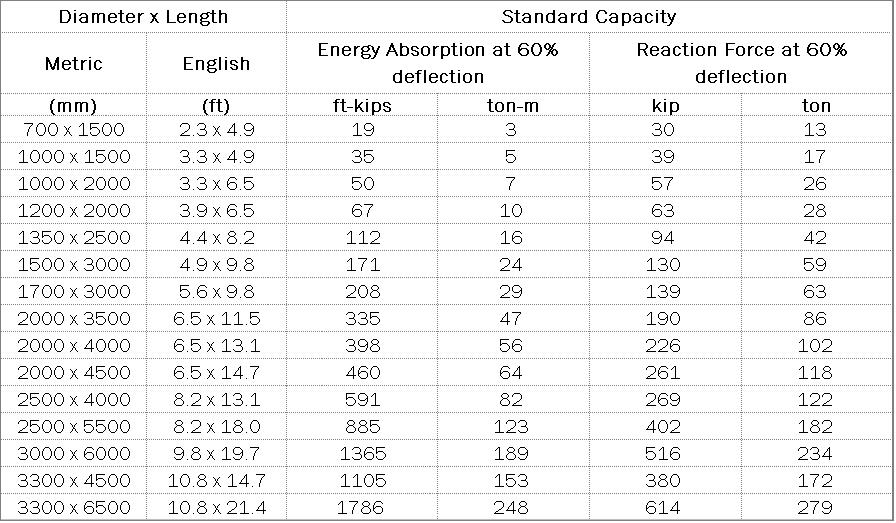

Rubber foam filled fenders performance table

Rubber Foam Filled Fenders are normally manufactured with standard capacity. Low reaction capacity, or high capacity also are available.