Marine Airbags to roll barges

Marine airbags are officially referred to ship launching airbags according iso 14409. It is used to roll ship, marine, barge and tugboats into water or ashore. Launch with marine airbag prior to slipway for small barges, ships. it is adopted widely by developing shipyards. Haul out the ship is another application of marine airbags, advantaged at decreasing cost of total maintenance and repair.

Marine airbags produced in one cylindrical body, connected by two concial heads, adopting holistic enlacing technology, giving a higher performance than common ship launch airbag. marine airbag is alike one inflatable roller bag, made of rubber material and fabric tire cord layers, advantaged at anti-aging, high elasticity and strong capacity. these features prompt airbags to be a good choice for ship launching and dry docking. there is a standard inner working pressure for each size rolling airbag while it reached biggest compression rate 70% and bearing capacity coming from.

Application of marine airbags

Known as ship launching airbag, ship launching is the governing use of marine airbag. his good wear-resistance, aging-resistance, flexibility and low maintenance provide more safety for ship launching works. airbags can be for launch frequently after every well storage. heavy lifting is small part of ship launching, airbags perform excellent at this like a jack. gradually, marine airbags are named heavy lifting airbags, widely applied to other fields like construction, gardening and heavy industry. heavy lifting airbags is enhanced marine airbag, more heavy duty than common airbag. besides these, airbags are alsoused for salvage & refloatation. they can float on water surface and underwater, high water pressure resistance and water resistance.

Known as ship launching airbag, ship launching is the governing use of marine airbag. his good wear-resistance, aging-resistance, flexibility and low maintenance provide more safety for ship launching works. airbags can be for launch frequently after every well storage. heavy lifting is small part of ship launching, airbags perform excellent at this like a jack. gradually, marine airbags are named heavy lifting airbags, widely applied to other fields like construction, gardening and heavy industry. heavy lifting airbags is enhanced marine airbag, more heavy duty than common airbag. besides these, airbags are alsoused for salvage & refloatation. they can float on water surface and underwater, high water pressure resistance and water resistance.

Construction

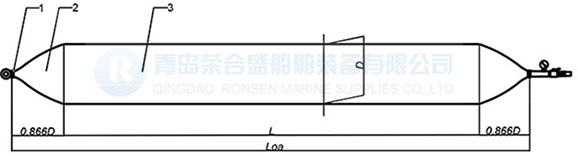

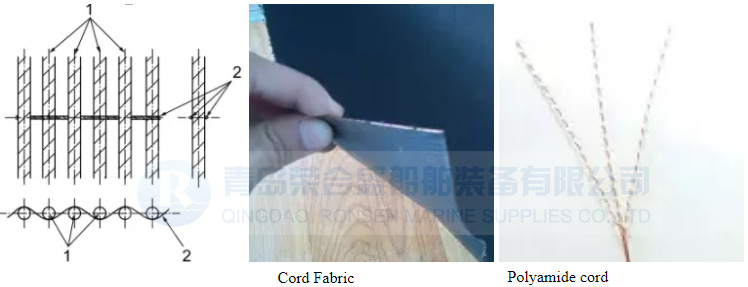

Material of an marine airbag include: rubber inner layer, synthetic tire cords layers and rubber outer layer. these materials structured airbag into one cylindrical body, jointed by two conical heads. Mouths of airbag installed with steel accessories to well kept inside pressure.

1.mouth 2.heads 3.body

1.mouth 2.heads 3.body

Classification&performance

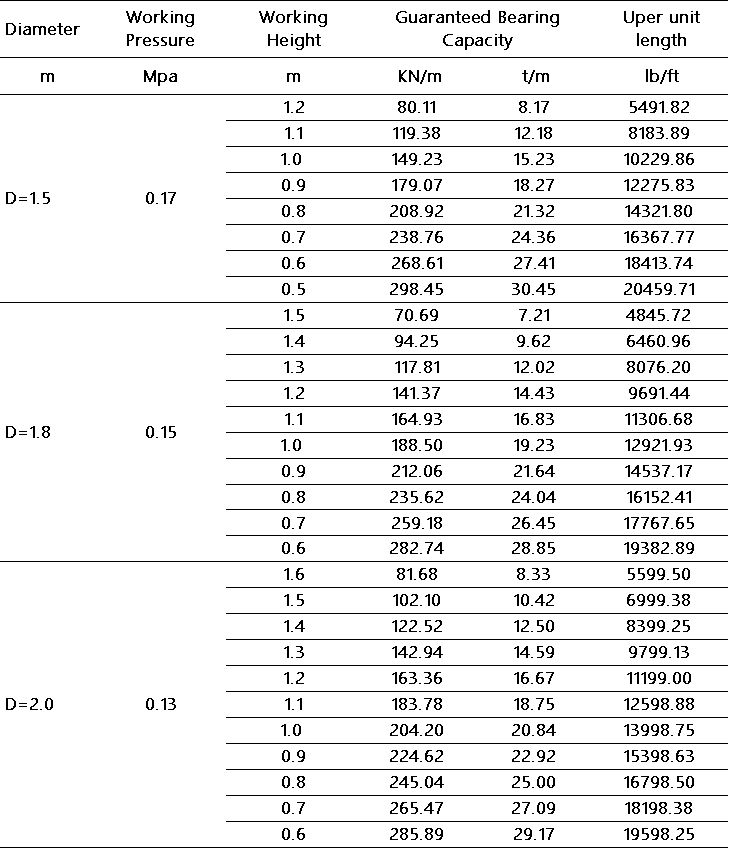

Size of marine airbag defined at diameter, EL(effective length), LOA(length overall) and reinforced layers. we have standard diameter which are: 0.8m,1.0m,1.2m,1.4m,1.5m,1.8m,2.0m,2.5m etc. el are possible to start from 7m~24m and layers from 4layer to 10layers around. our airbags can be deflected to 70%, performing higher capacities than iso 14409. here below is the performance sheet for common size.

Tests

Our ship launching airbags are manufactured and tested under standards requirements of iso 17682 and iso 14409. the necessaried inspected items before delivery for an airbag are: appearance, dimension and tightness.

Our ship launching airbags are manufactured and tested under standards requirements of iso 17682 and iso 14409. the necessaried inspected items before delivery for an airbag are: appearance, dimension and tightness.

Appearance: the appearance of an air bag shall be smooth, glossy and without blemish such as crack, blister, delimination, pits or impurities.

Dimensional tolerances: length and diameter of an air bag shall be measured with rated working pressure, within 3%.

Gastightness: while without carrying any load, fill air bag till internal required pressure, record the pressure and compare it after 1 hour. loss is no less than 5% than qualified.